Meet Our Chief Engineer – Mr. Aaron

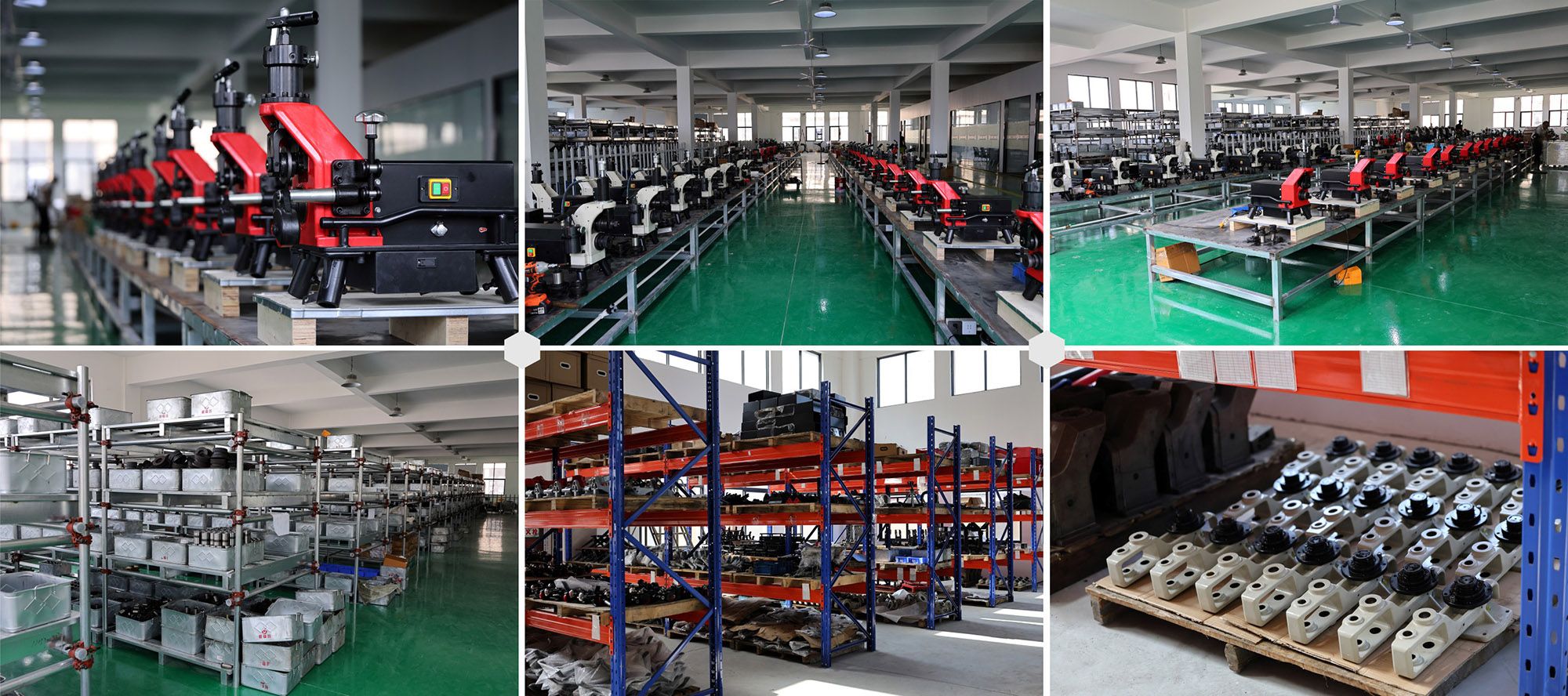

With more than 200 machine structures and tools developed under his direction, Mr. Arron brings both experience and innovation to our engineering team. His work has shaped much of what we build today—and has been recognized by several international brands through successful roll grooving machine development and technical cooperation.

Arron has a strong focus on hydraulic system design, a key component in many of our grooving machines and tools. His systems are known for their reliability, clean layout, and long service life.

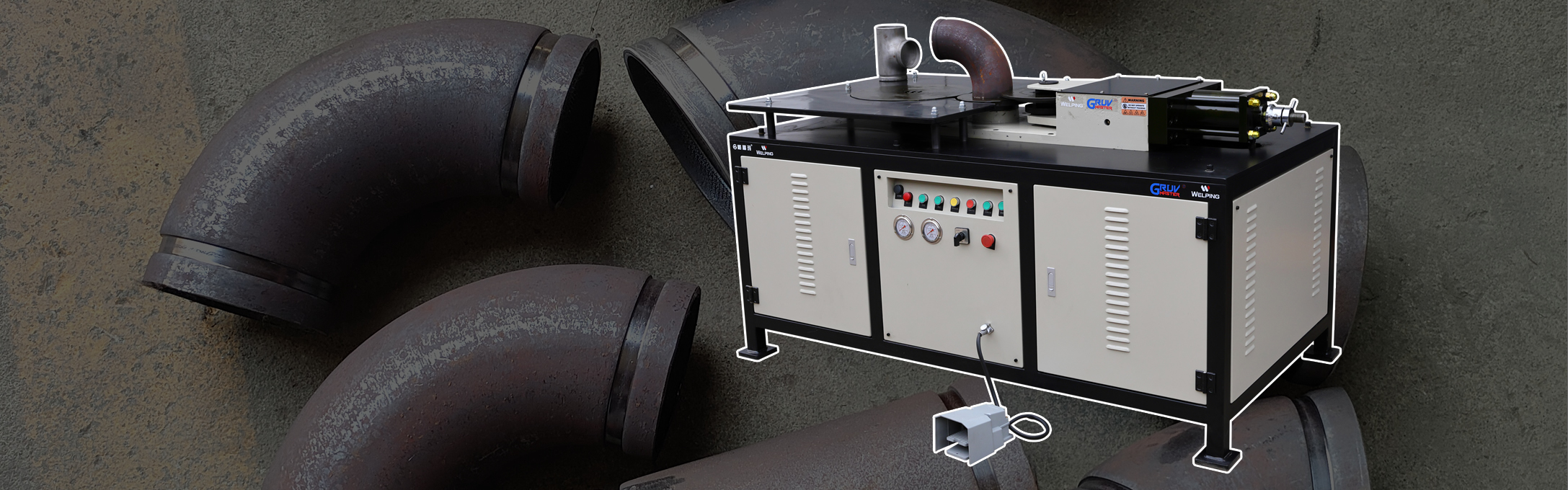

Most recently, he led the development of a fully sealed, integrated hydraulic pump—a major breakthrough in grooving machine hydraulics. The new design supports OnePush™ fast feed-in, and TitanSeal™ requires no oil change or maintenance for 2–3 years, and significantly improves overall system stability.

A constant learner, Arron draws insight from field applications, customer conversations, and leading designs in the market. He’s quick to spot the logic behind a good design—and turn it into ractical, forward-thinking solutions.

Chief Engineer – Mr. Aaron