How To Maintain And Care For A Roll Groover Machine?

Conservation Methods

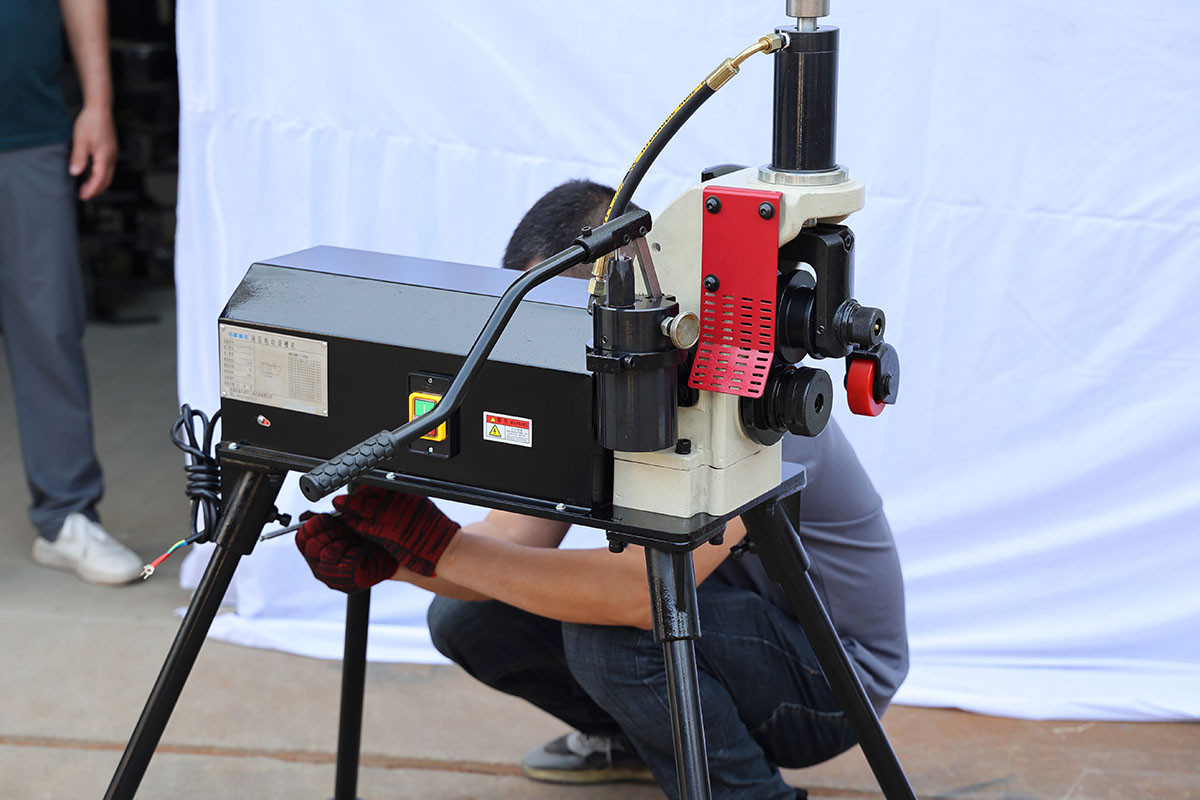

Ensuring proper maintenance of a roll groover machine is crucial for efficient operation and extending its lifespan.

Firstly, conduct regular checks on the lubrication system to ensure an adequate supply of quality lubricating oil, reducing wear and tear on mechanical components.

Secondly, clean the rollers periodically to prevent the accumulation of debris, which may otherwise impact processing quality. Regularly inspect the electrical system, ensuring secure circuit connections to prevent equipment damage due to electrical faults.

Additionally, pay attention to the regular inspection and tightening of bolts and nuts on the equipment to maintain structural stability.

When performing maintenance, use appropriate tools and equipment, and follow the maintenance manual or guidelines provided by the manufacturer.

Lastly, train operators on correct maintenance procedures to ensure safe operation, enhance equipment reliability, and stability.

Through these maintenance practices, the roll groover machine can be kept in optimal condition, improving production efficiency, and minimizing the risk of malfunctions.

FAQs