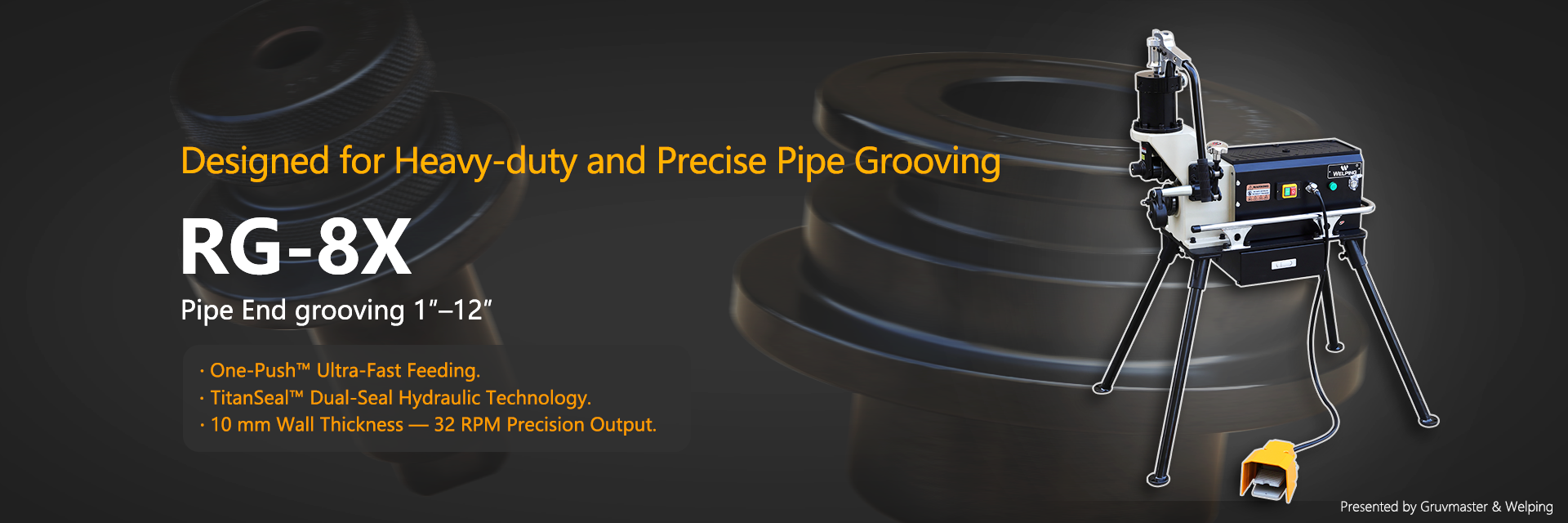

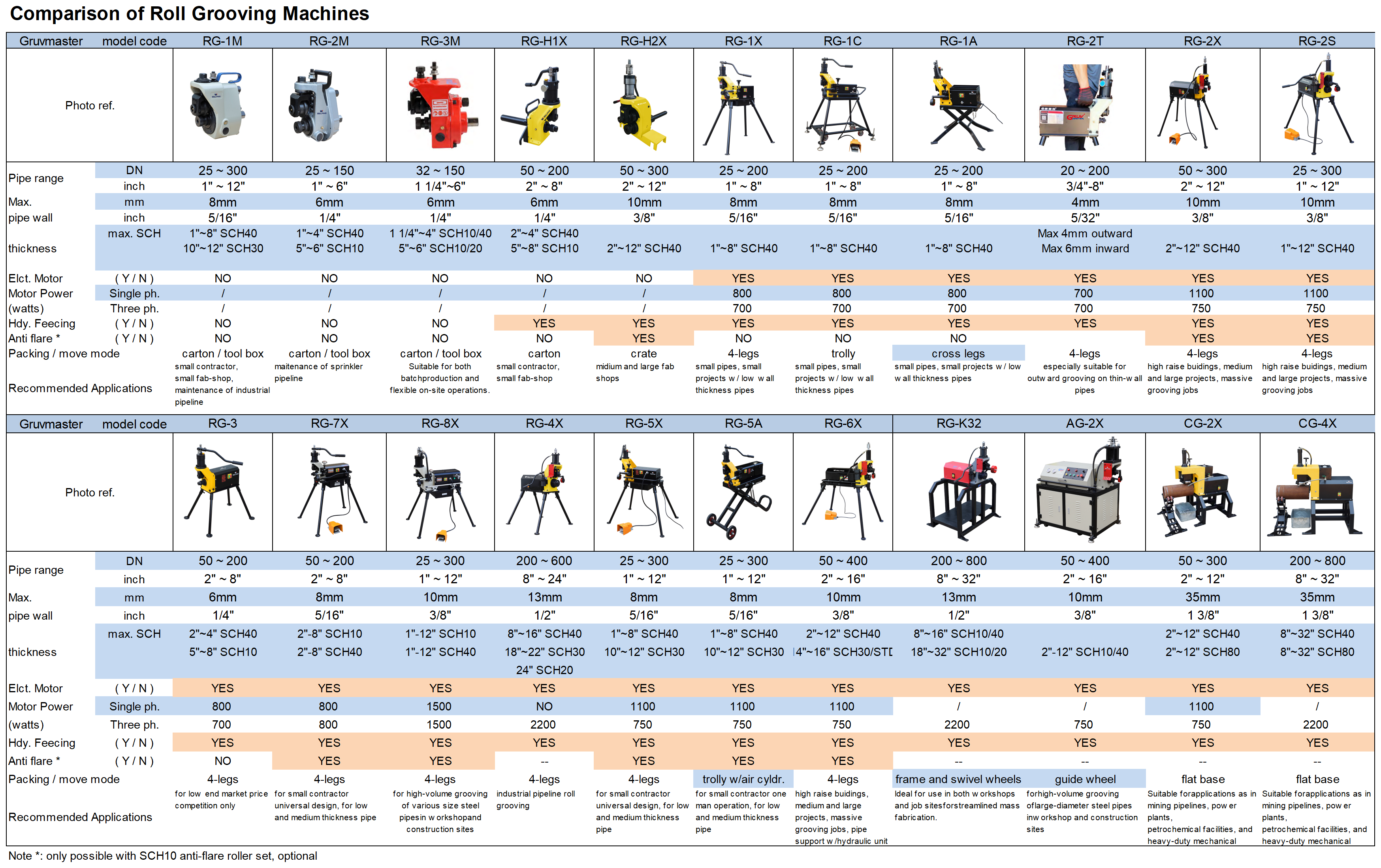

With 10 models available, our hydraulic roll grooving machines cover 1''–12'' pipes. From light-duty to heavy-duty, there’s always a durable and efficient solution to match your specific project needs

Innovative Technology-leading Roll Groovers Manufacturer

Discover Gruvmaster's cutting-edge pipe fabrication solutions:From Roll Grooving to Pipe Cutting, Groove Cutting, and Hole Cutting, our machines offer precision, efficiency, and safety for diverse pipe work needs.

Our heavy-duty hydraulic roll grooving machines cover 8''–32'' pipes with 3 model options. Each size combination is engineered to meet tough demands, ensuring reliable performance and durability in challenging projects

Automatic roll grooving machines with 2 models available, covering pipes up to 24''. Featuring reliable hydraulic control, this series delivers professional efficiency and precision, especially ideal for workshop-based batch operations

Automatic roll grooving machines for pipe fittings, covering 2''–24''. Equipped with a reliable hydraulic control system and exclusive anti-pipe-walk design, ensuring stability, precision, and efficiency in professional workshop operations

Manual roll grooving machines, lightweight and flexible, suitable for independent manual grooving or combined use with power drives and threading machines. A versatile solution designed for portability, ease of use, and reliable performance

Gruvmaster groove cutting machines feature an exclusive structural design, handling pipe sizes up to 32''. Especially suitable for mining pipelines and ultra-thick wall pipes, delivering reliable strength, precision, and long-lasting performance

Groove end reforming machines, designed for correcting pipe fitting flare ends. Perfectly matched with fitting roll grooving machines, ensuring precise reshaping, stable connections, and improved efficiency in professional grooved piping projects

Electric pipe cutting machines with 5 models available, covering 1/2''–20'' pipes. From light-duty to heavy-duty, suitable for steel, stainless steel, copper, and aluminum pipes — always the right cutting solution for you

ABOUT US

New Equipment for Roll Groovers and Cutting Machines

News Center

- Gruvmaster AG-8Z Roll Grooving Machine: A Practical Update Based on Real UseJan 8,2026The Gruvmaster AG-8Z roll grooving machine has been updated based on real job-site use. The new version features a larger hydraulic power unit, a telescopic handle for easier movement, and an expanded pipe size range from 1″ to 16″.

- Gruvmaster RG-4X Pro: Structural Updates Based on the RG-4XJan 5,2026This article explains the structural updates of the Gruvmaster RG-4X Pro based on the RG-4X. The upgrades focus on practical improvements, including a frame with integrated storage, a larger grooving assembly, reinforced pipe support, and upgraded positioning rollers. These changes enhance stability, durability, and control during long-term roll grooving operations.

- Gruvmaster Roll Grooving Rollers: Plated vs. Stainless SteelDec 30,2025Roll grooving machines require different roller materials for different pipe conditions. This article compares plated rollers and stainless steel rollers used on Gruvmaster roll grooving machines, focusing on thin-wall pipe applications, groove quality control, durability, and cost considerations. Selecting the correct roller set based on pipe wall thickness helps improve grooving consistency and overall processing reliability.